Table of Contents

VCS Swept Sine Testing

Create New Test

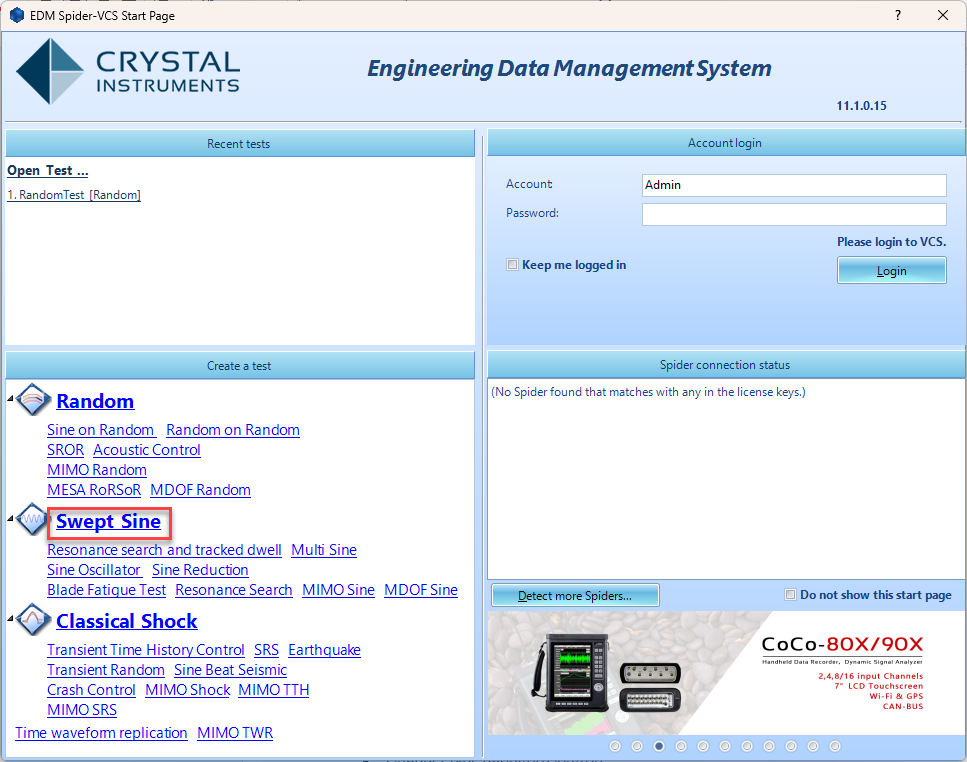

To create a new test, first open up EDM. On the VCS Start Page, select Swept Sine under the Create a test tab.

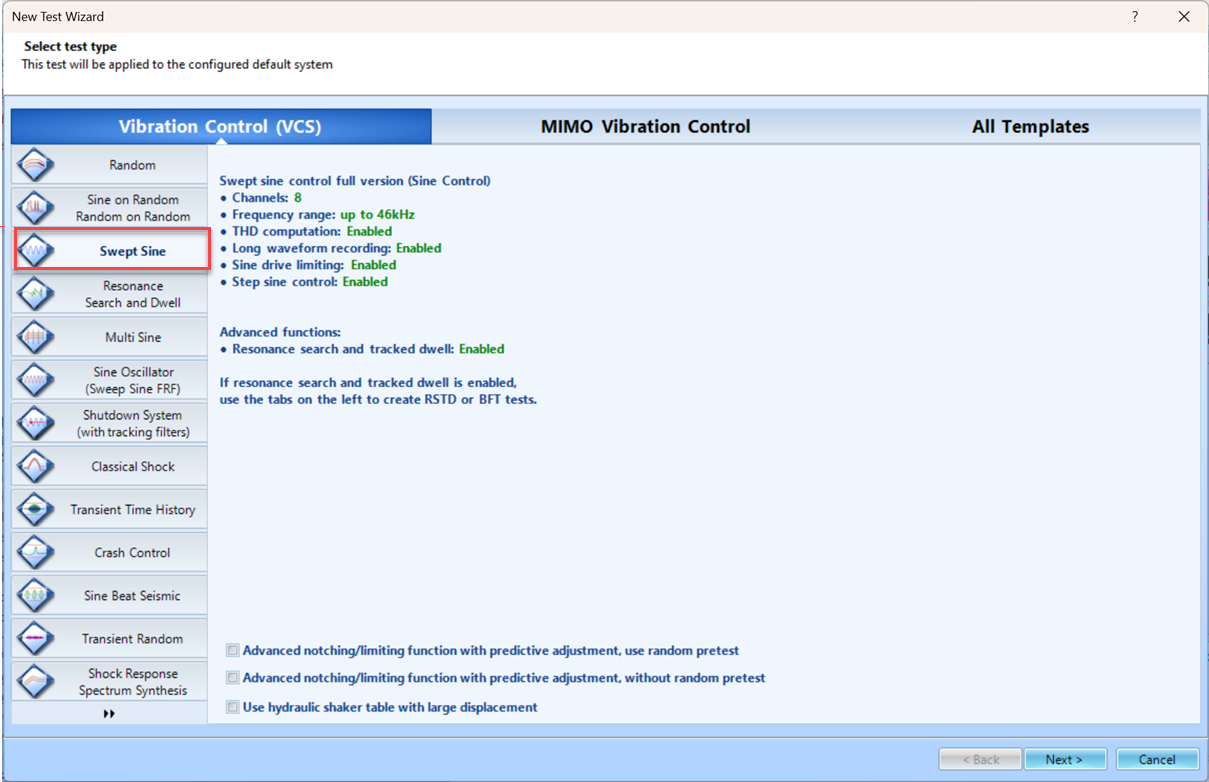

The New Test Wizard will now open up. From here, select Swept Sine again and then press Next.

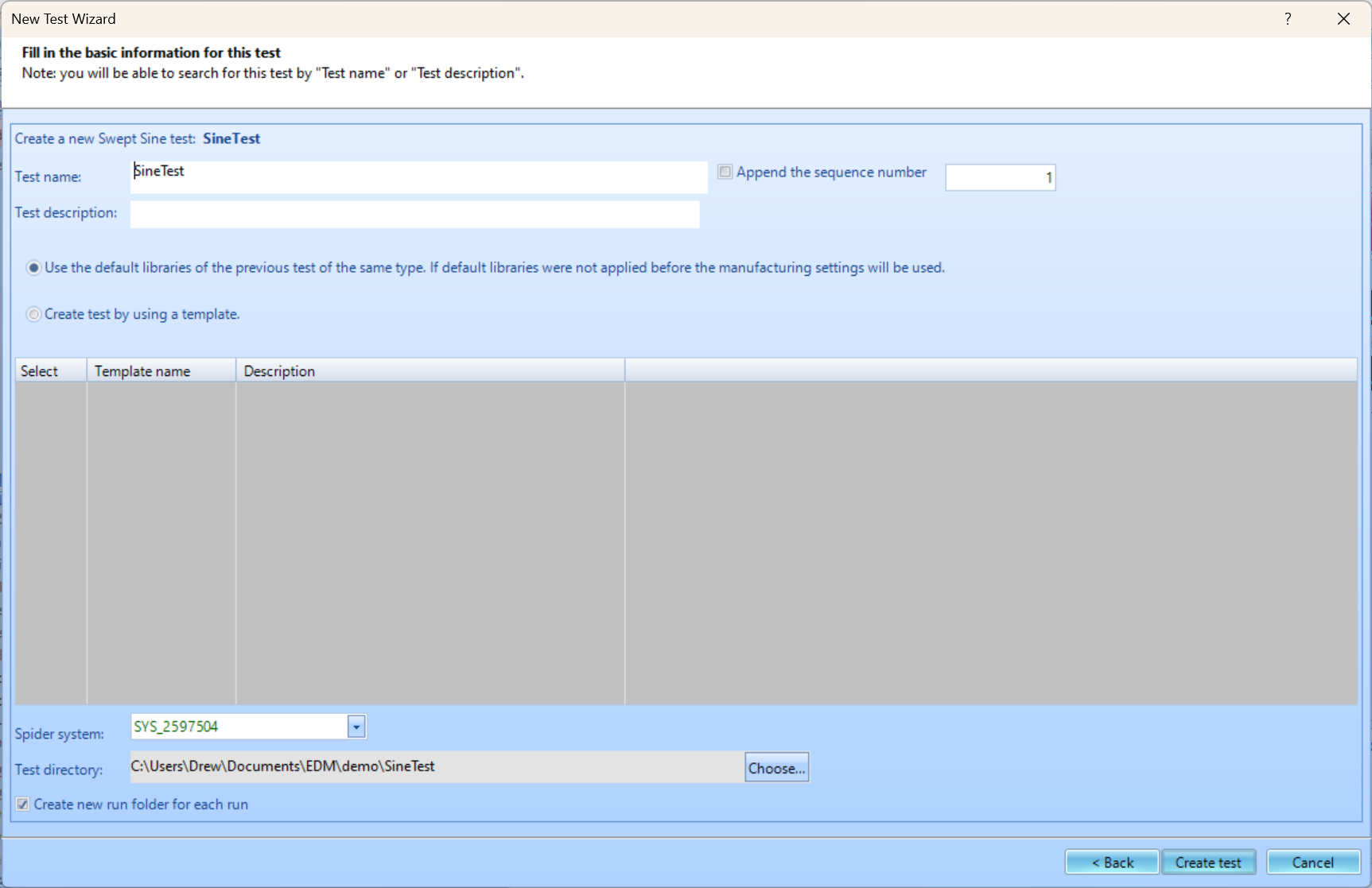

Finally, give the test a name and select the Spider system that will be used to run the test. Once all is complete, press Create.

Test Configuration

The test will now need to be configured to run. This includes inputting information regarding the shaker, creating the schedule for the test to follow, and determining the parameters for the frequency analysis. To access the Test Configuration menu, press the Config button that can be found on the right side of the screen.

Shaker Parameters

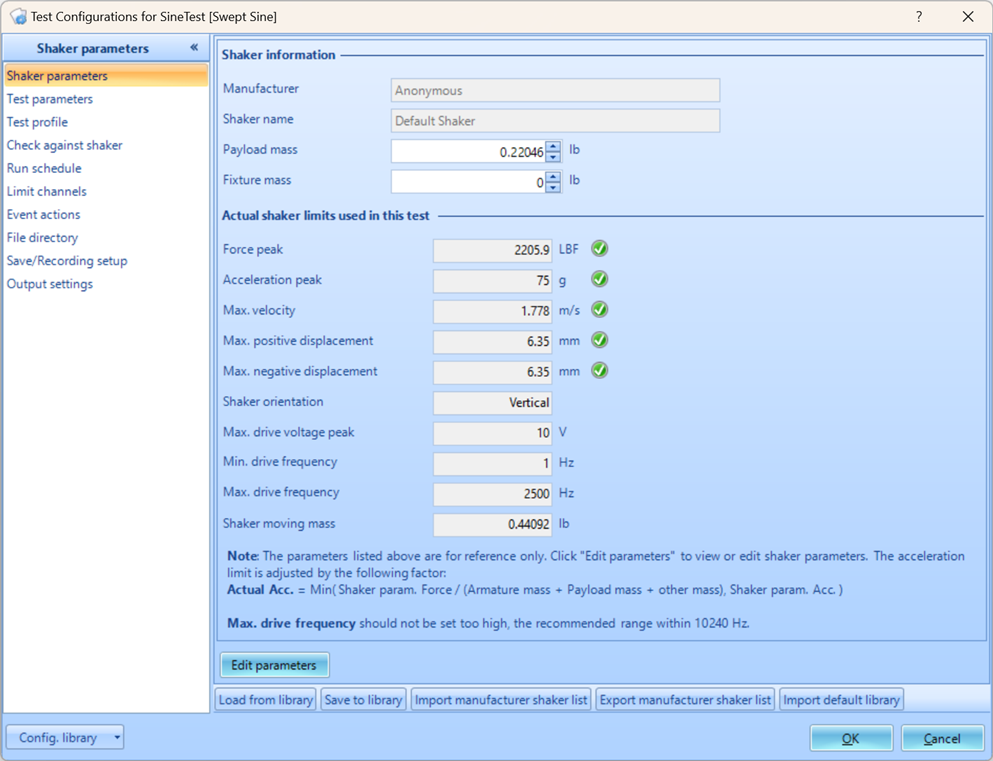

Shaker Parameters

Click on Edit Parameters and enter the information from the shaker specifications. This is important for the safety of the shaker and testing unit.

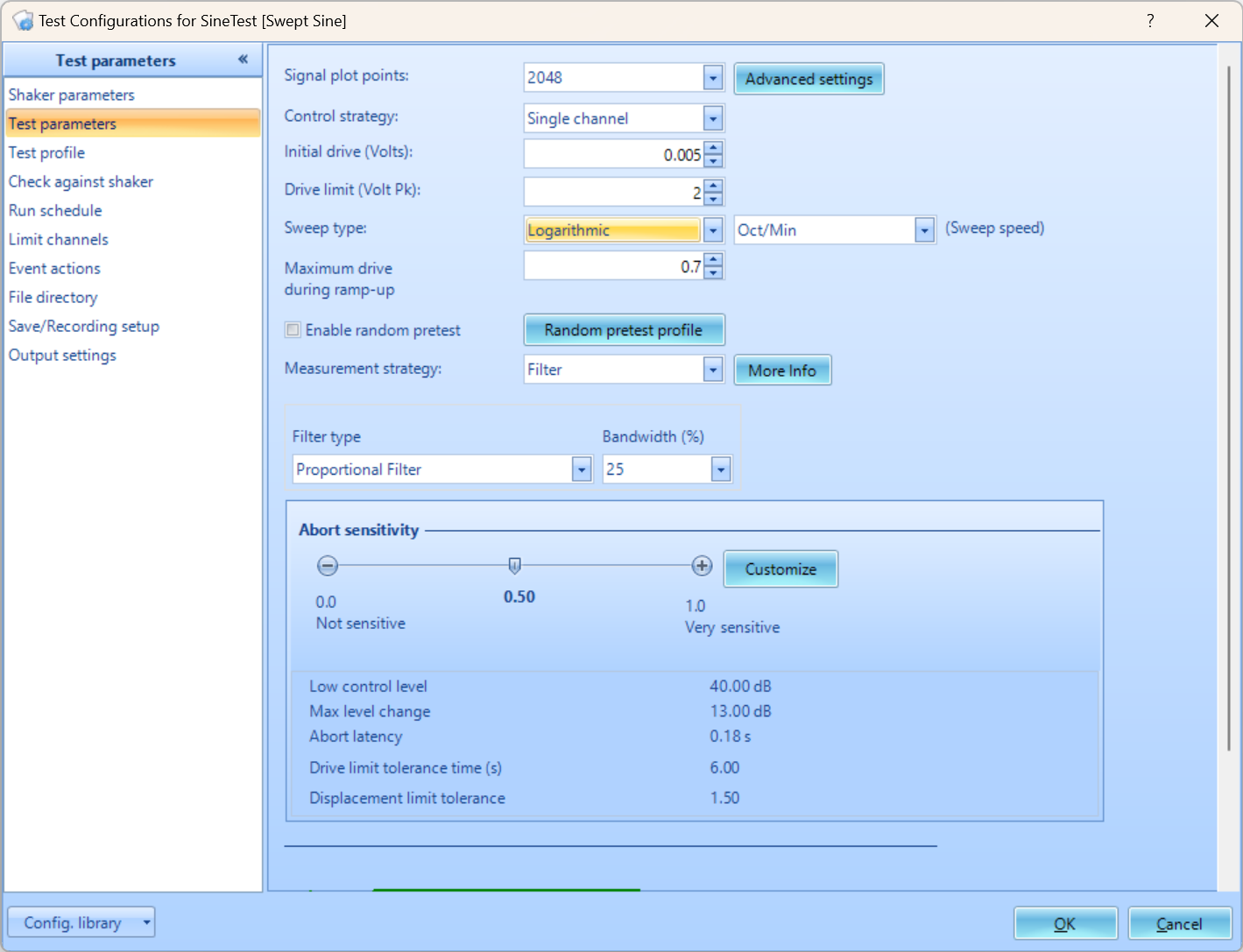

Test Parameters

The Test parameters section in the Test Configuration window has settings for the analysis parameters, abort sensitivities and control strategy.

Control Strategy: Determines whether one or multiple control channels are used, and how the composite control signal is generated (if multiple channels are used).

Sweep Type: Linear or Logarithmic. When the Sweep Type is Linear, the Sweeping Speed is in the unit of Hz/Min (Hertz per minute); When the Sweep Type is Logarithmic, the Sweep Speed can be defined in unit of Octave/Min or Decade/Min.

Measurement Strategy: Defines how the sine waves are measured. The selections are: Filter, RMS, Mean and Peak. In a perfect world when the sine signals have no distortion, all the measurement strategies will generate the same results. When signals are distorted, the controller will generate different drive magnitude by selecting different Measurement Strategy.

Filter: Only measures the energy in control frequency, ignores harmonics. This tends to under-estimate the control measurement and over-test the system. When Filter is selected, the measurement only takes the component at fundamental frequency into consideration while the energy out of band is ignored. The center of the filter follows the current sweeping frequency and Filter type and Bandwidth determine how the filter bandwidth is changing and the bandwidth, therefore, the filter is called tracking filter. When the filter type is Proportional Filter, the bandwidth is changing proportionally to the current sweeping frequency. When the filter type is Fixed Filter, the bandwidth is fixed regardless of the current sweeping frequency.

RMS: Calculates the total energy, including harmonics, by taking RMS in time domain (which is equivalent to RMS in frequency domain by Parseval’s Theorem). During this, the RMS calculation is scaled by 1.4x to be consistent with other measurement strategies. The “frame size” of the RMS is inversely proportional to width of tracking filter.

Peak: Calculates the total energy, including harmonics, by taking Peak in time domain. This tends to over-estimate the control measurement, and under-test the system, because it is possible for many sine components to peak at the same time which results in an inflated estimate.

Mean: Similar to RMS, except we take absolute value of all points in time domain and then calculate the mean.

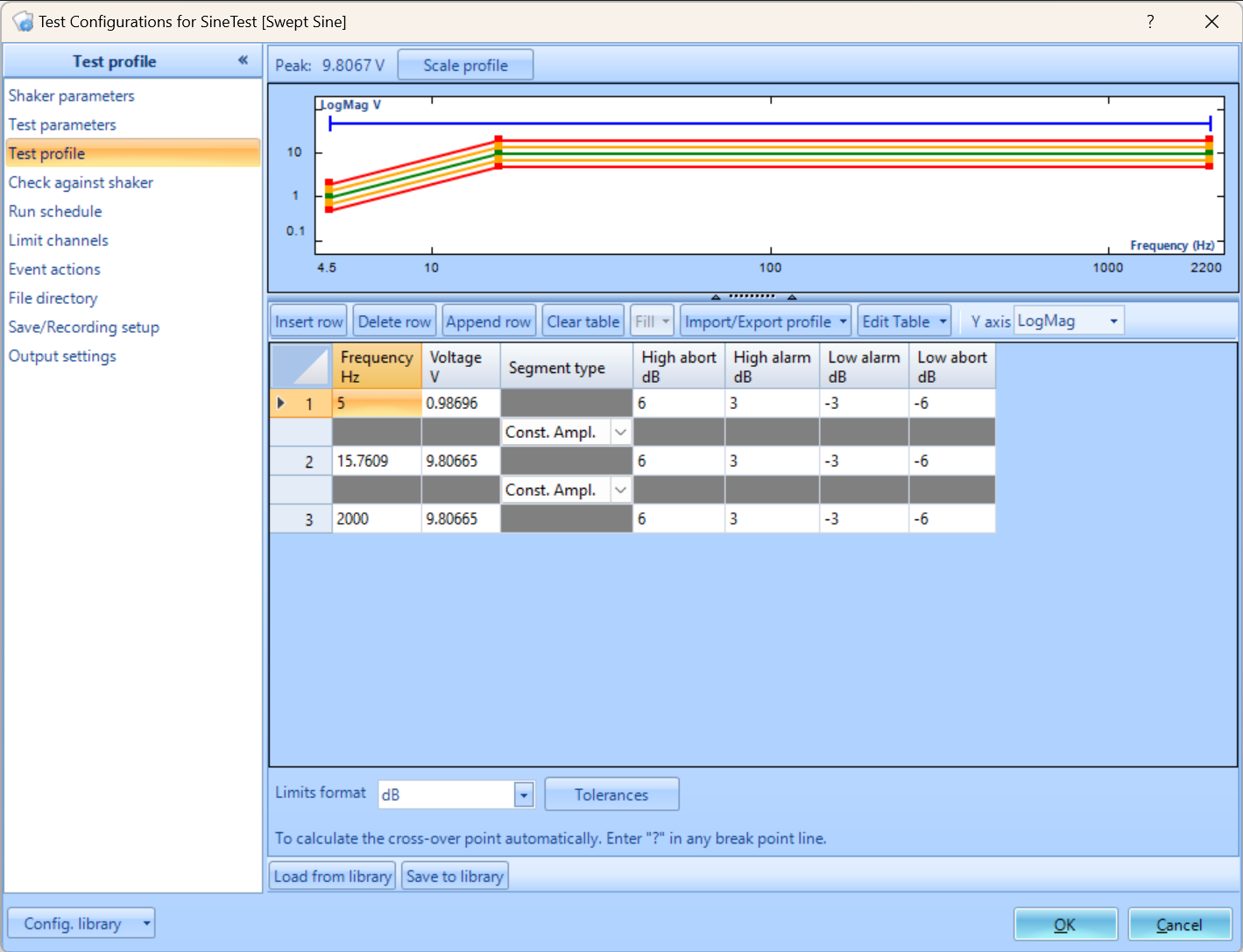

Test Profile

The test profile is defined in the Test Profile section of the Test Configuration window. A graphical preview of the profile plot is displayed above, with a breakpoint table below for entering the profile. CSV import / export is also supported as an alternative to profile editing.

Breakpoint Table: Breakpoints can be added via Insert row, Delete row and Append row. Use Clear table to clear out all rows except for the first and last row.

Breakpoint Calculation: In the profile editor, EDM can calculate the crossover point given a specified slope and point value. If a ‘?’ is entered as a Frequency or Amplitude value, EDM will interpolate that value given the slope before and after that point.

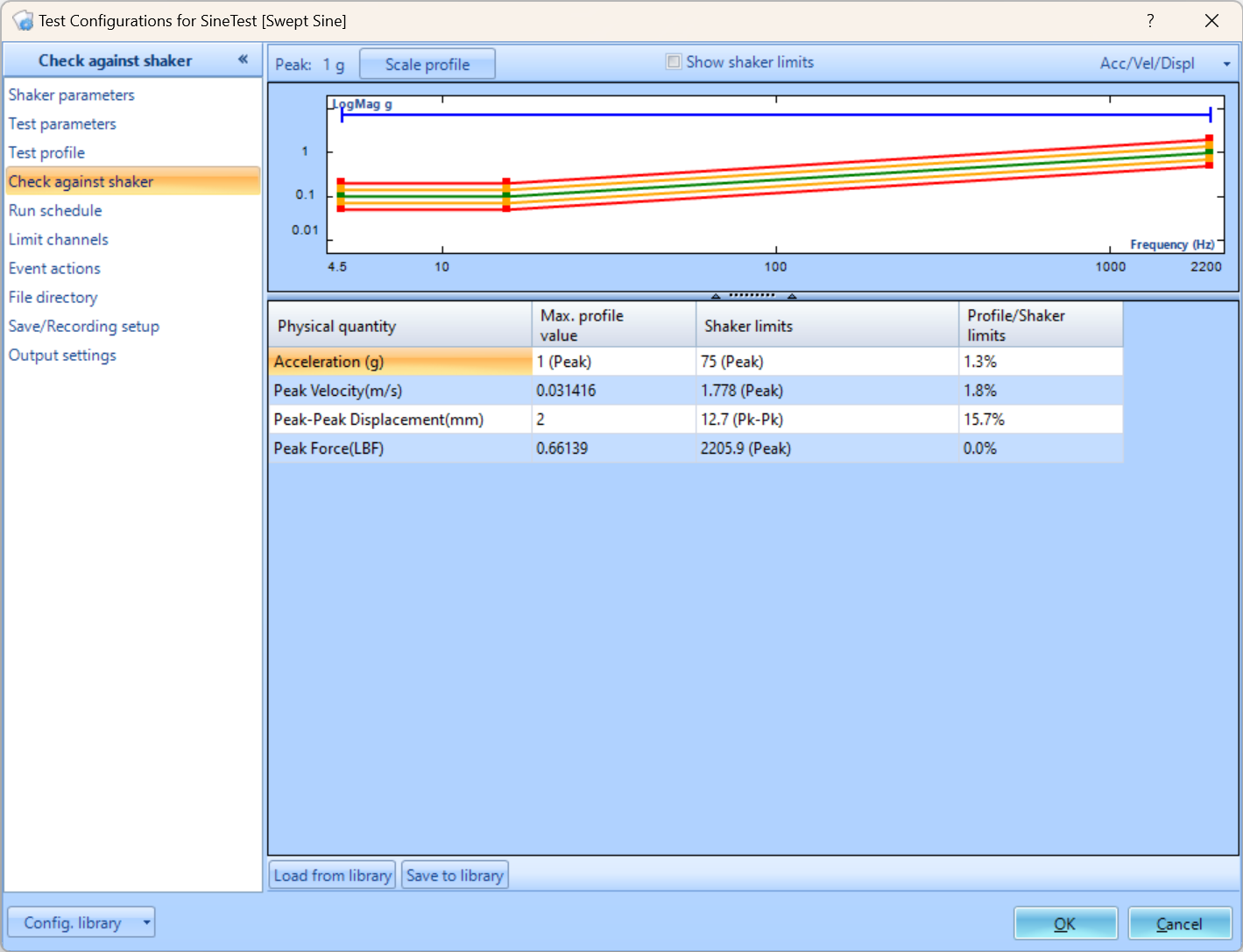

Check Against Shaker

This tab gives the user an indication of the percentage of the shaker performance would be required during full level test, using the defined profile. The profile and alarm/abort signals are plotted above, while the peak values per current profile and the shaker limits are listed underneath. The percentage value of Profile/Shaker limits provides the user the information about what level the shaker will work per current profile.

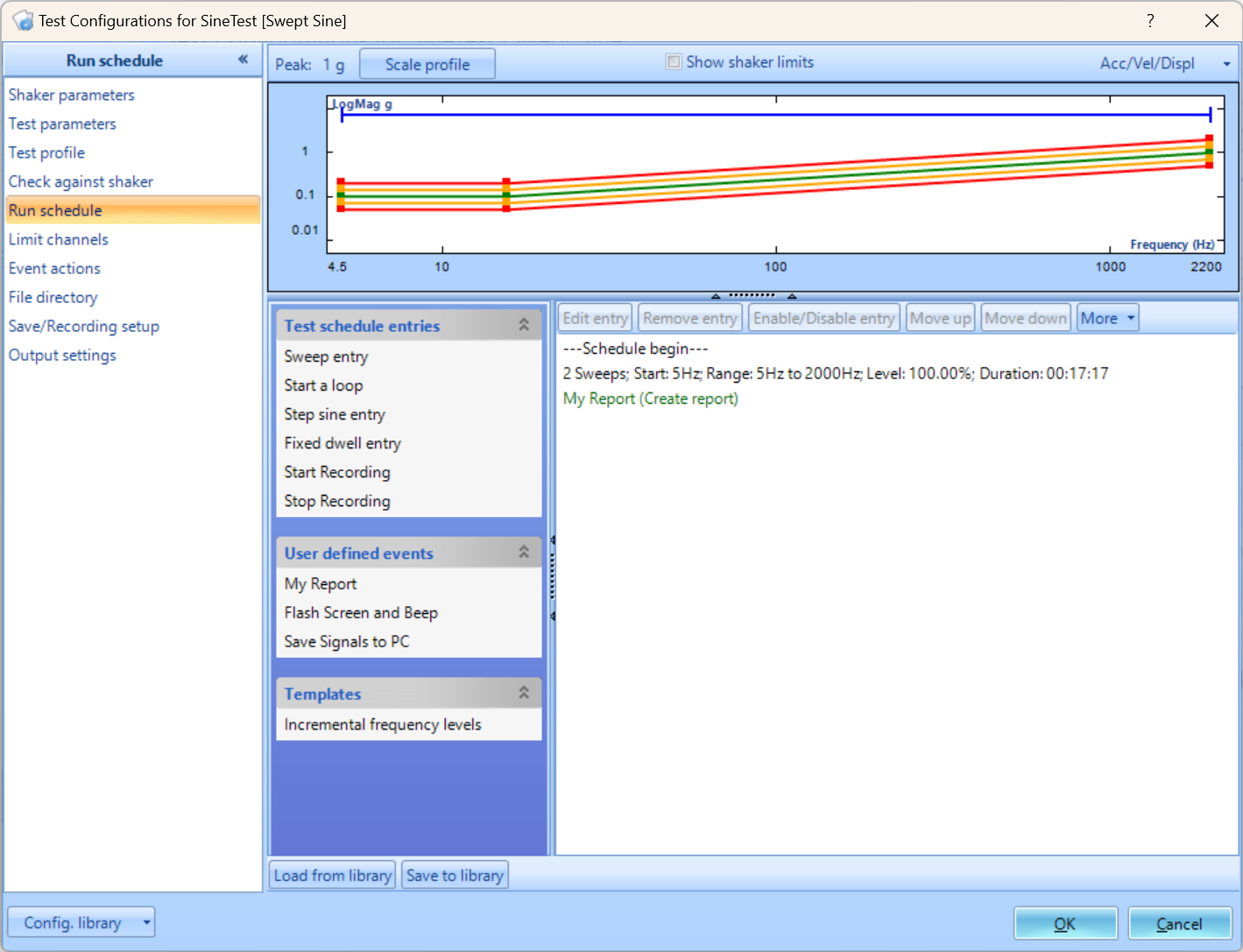

Run Schedule

The Run Schedule sets the sequence of test stages that will be executed when the test is run.

Sweep Entry: The Sweep entry types can be either a fixed frequency range at a fixed sweeping speed, or over a fixed time. Fill in the fields Time per sweep or Sweep speed according to the display: the other field will be shown with the calculated value. Selecting Test Profile (up) will begin from the lowest frequency and go towards the highest frequency, as defined by the Test Profile. Selecting Test Profile (down) will begin from the highest frequency and go towards the lowest frequency. Choosing Custom will allow to manually pick and decide the start and stop frequencies.

Input Channels

The input channels will now need to be set up. All sensors will to be properly configured before testing. The Input Channels menu can be found through Setup → Input Channels.  Channel Type

Channel Type

Control vs. Monitor. When running a test, there will need to be at least one control sensor. The control sensor is used to monitor the actual vibration levels that the shaker is producing. It then sends this data to the controller so that it maintains the targeted profile. This sensor should be mounted somewhere on the shaker/slip table itself, not the Device Under Test (DUT). Monitor sensors will show the levels that the DUT itself is experiencing.

Measurement Quantity

Defines the physical unit that will be measured by the sensor connected to the channel.

Sensitivity

Sets the proportionality factor for the measurement (millivolts per engineering unit) given as a parameter of the sensor.\\Input Mode

There are five modes in which the inputs can operate:

DC-Differential- In the DC-Differential mode, neither of the input connections is referenced to the local ground. The input is taken as the potential difference between the two input terminals, and any potential in common with both terminals is canceled out. The Common Mode Voltage (CMV) will be rejected as long as the overall input voltage level does not saturate the input gain stage. Beware that very high CMV will cause clipping and may damage the input circuitry. Signals with a nonzero mean (DC component) can be measured in this mode.

DC-Single End- In single-ended mode, one of the input terminals is grounded and the input is taken as the potential difference of the center terminal with respect to this ground. Use this mode when the input needs to be grounded to reduce EMI noise or static buildup. Do not use this mode when the signal source is ground referenced or ground loop interference may result. This mode also allows signals with a non-zero mean to be measured.

AC-Differential- AC-Differential is a differential input mode that applies a low-frequency high-pass (DC-blocking) analog filter to the input. It rejects common mode signals and DC components in the input signal. Use this when DC and low-frequency AC voltage measurements are not required or when a DC bias voltage is present. The analog high-pass filter has a cutoff frequency of -3dB at 0.3 Hz, and -0.1dB at 0.7 Hz for the IEPE input mode.

AC-Single End- AC-Single End grounds one of the input terminals and enables the DC-blocking analog filter. Use this mode for non-ground referenced sources where measuring the DC or low-frequency components are not required. It shares the same high-pass filter as that of AC-Differential.

IEPE (ICP)- All Crystal Instruments products support IEPE (Integral Electronic PiezoElectric) constant current output type input channels. IEPE refers to a class of transducers that are packaged with built-in voltage amplifiers powered by a constant current. These circuits are powered by a 4 mA constant current source at roughly 21 Volts.

Charge- Some sensors provide a high-impedance charge output. Usually, these are high-sensitivity piezoelectric units that lack a built-in voltage mode amplifier (i.e. IEPE), allowing them to be used in high-temperature environments. The Spider-81 front-end module has a built-in charge amplifier that allows the system to read the output of these sensors

Running the Test

Now that all of the parameters for the test have been setup, the test is ready to run. Here are the final steps to start the test.

- Press the Connect button to connect to the controller.

- Press the Run button.

- The Spider Check List will now appear. Here you can check the settings of the test and verify that all is set up properly. Press Start once this has been verified.

- The Pre-Test will now begin. This will verify that the control loop is properly established and provide data that the control loop needs.

- The test is now running